Bolts in the Future

Mission

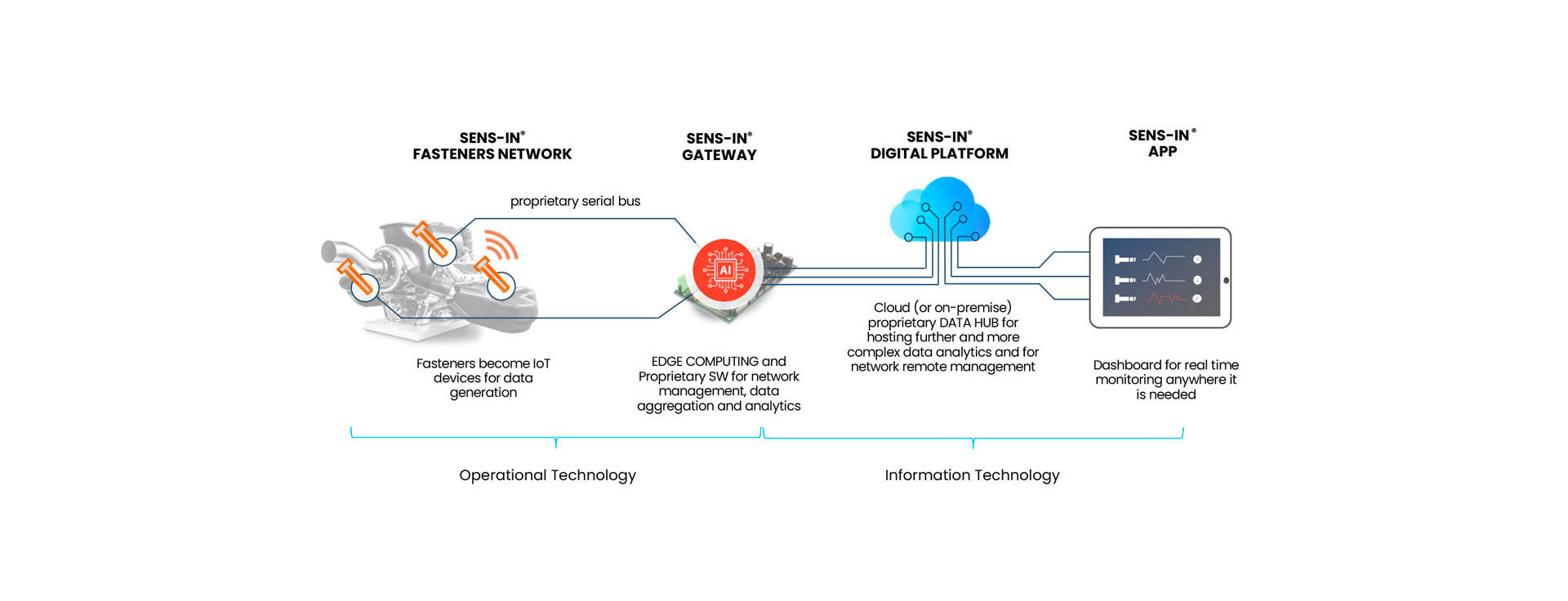

Sens-In® is an innovative device focused

on developing Internet of Fasteners solutions.

Fully digitise mechanics by extracting data

from where it has never been extracted before,

through robust, industry ready, easy-to-apply,

intelligent bolts.

-

Sens-in® Bolt

-

Sens-in® S-tag Bolt

Application view

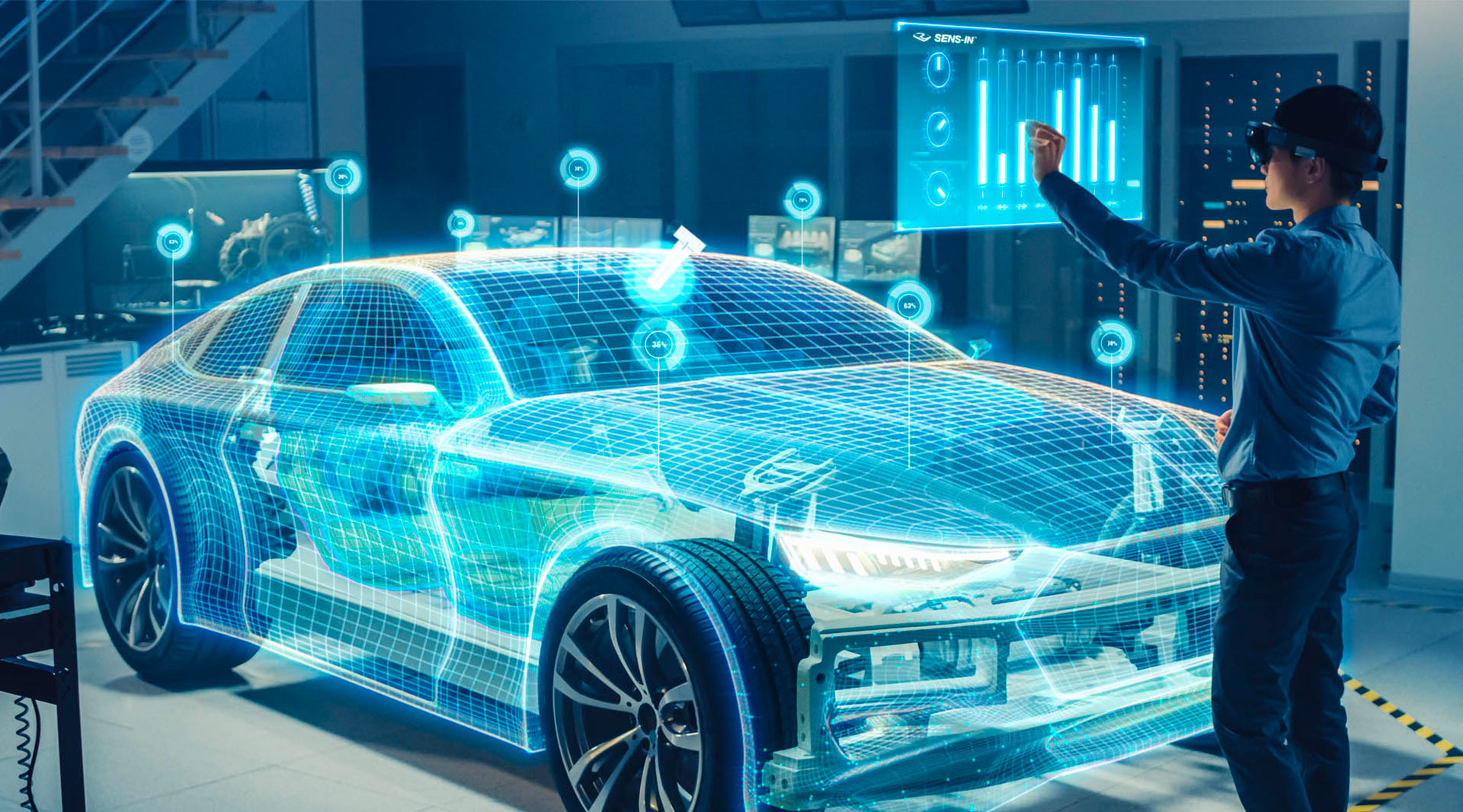

Reduce machine downtime

on high added value processes, both planned and unplanned, and optimising maintenance effectiveness through migration from a preventive maintenance approach to a prescriptive one.

Easily set the correct preload during bolt installation

Instead of controlling only the tightening torque, thus obtaining the correct bolted joint tension. For critical and expensive applications.

Self-loosening - Lost function Alert

Real time alerting of bolts loosing their nominal pre-load or increased vibration levels, which can be early stage clues for damages or malfunctions that have direct impact on product quality.

Structural Health Monitoring

For critical structures in aerospace & construction (bridges and tunnels) markets. KEY FOR SPACE.

Correct retooling

Quickly and neatly check a production line has been correctly retooled for new part types, thanks to wireless tag bolts.

.png)

BI-REX

OPEN INNOVATION

Sens-in® Srl is proud to announce its active participation—alongside other partners—in two new collaborative innovation projects funded through the Bi-REX Competence Center.

These initiatives are supported by PNRR funds (Mission 4, Component 2, Investment 2.3) from the European Union under the Next Generation EU program, with the goal of promoting and supporting the technological and digital transformation of the country.

Project co-financed by the PR FESR Emilia-Romagna 2021–2027.

SENS IN SRL has received a public contribution under the regional PR FESR 2021–2027 call.

The project involved the hardware and firmware development of the electronic boards for both wired and wireless product lines, with the aim of optimizing performance, reliability, and scalability.

At the same time, the aerosol jet printing technology was experimented with—an advanced additive printing technique for the direct deposition of strain sensors onto complex surfaces, with a view towards future industrialization.

This investment is part of the long-term strategy focused on innovation in embedded sensors and advanced structural monitoring, with integrated and intelligent solutions for the aerospace, automotive, energy, and industrial sectors.