Background

Founded in 1950, Poggipolini S.p.A. is a leading Italian company, expert in the design and production of critical and structural fasteners and precision parts, as well as systems for the aerospace, space, defense and automotive (hypercar and F1) industries.

We provide advanced engineered fastening solutions.

In 2020 Poggipolini founded Sens-In Srl, a spin-off of Poggipolini.

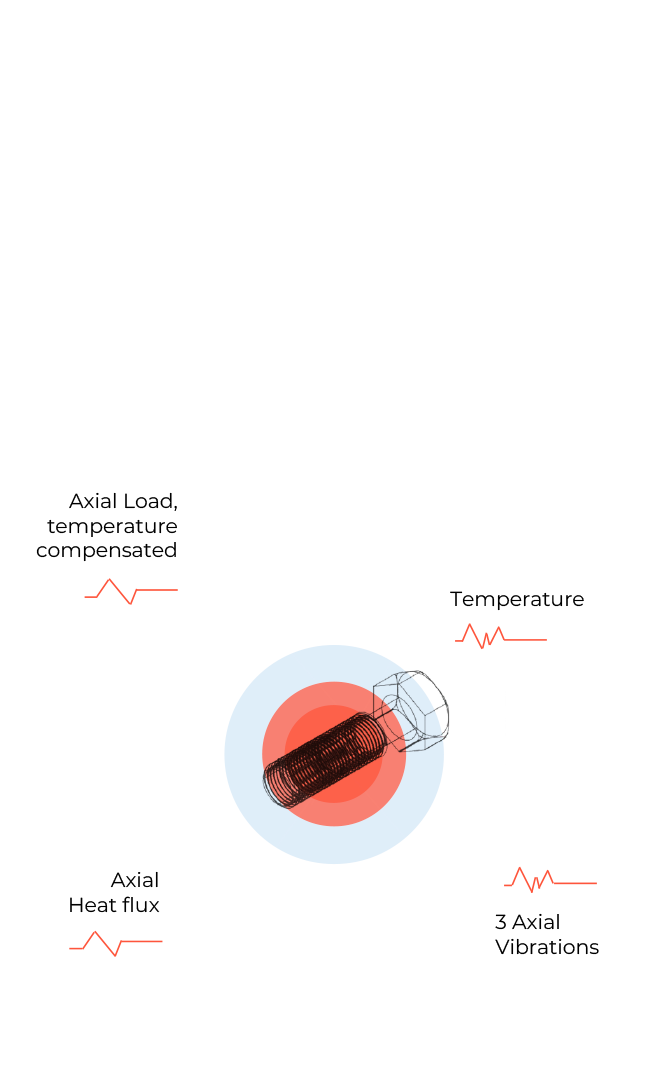

Sens-in® technology overview

Our solutions

Our technological vision foresees the choice of sensing solutions that provide data in real time for continuous monitoring, and digitalization as close as possible to where data is generated.

Main Technical Features,

to be customised to the specific need:

- System Layout is customizable on request

- Digital output from smart bolt:

high immunity to electromagnetic fields, long distance transmission, operative Bolt Temperature range -40°C (-60°F) ÷ +60°C (+140°F)

- Analog output from smart bolt:

high temperature possible applications up to 250°C (~480°F) depending on sensors type

- Connectivity:

wired with axial connector – wireless

- AES-128 Encrypted output from smart bolt

- Mechanics:

Dimensions from M6 (¼’’) thread up, custom materials and geometries, corrosion proof design

- IP67 Ingress Protection

Why we use strain gauges

Tech

comparisons:

why we use strain gauges